ALL SPECIES CAN REGENERATE GENOMES AND CELLS, from bacteria to humans. Some creatures—such as spiders and starfish, even mammals like the African spiny mouse—have the ability to regrow whole appendages.

While biologists are investigating how to replicate those sorts of feats in humans, biomedical engineers like Assistant Professor Keekyoung Kim at UBC’s Okanagan campus, are discovering ways to join proteins and various biological molecules to construct functional living tissues and artificial organs.

“Science has long been working towards ways to minimize or eliminate the rejection risks faced by tissue transplant patients,” Kim says. “While the goal of using a patient’s own genetic material to grow a body tissue is still a long way off, we are making advancements in that direction.”

“We hope this new bio-ink will help researchers create improved artificial organs and lead to the development of better drugs, tissue engineering and regenerative therapies.”

Inside UBCO’s Integrated Bio-Micro/Nanotechnology Laboratory, Kim and his research team investigate tissue regeneration. They’re also focused on creating tissues on “chips” for drug trials, thereby eliminating the need for animal and human testing. Their interdisciplinary research combines engineering, science and medicine within biomedical, pharmaceutical and environmental applications.

Using techniques such as 3-D printing, also known as bio-printing, Kim says his team is at the cutting-edge of “organ-on-a-chip” research, providing important resources to other researchers in health care.

Inkjet, laser-assisted or extrusion printing processes can all be used to bio-print tissue, where the ink (or bio-ink) is a combination of cells and biomaterials, also referred to as hydrogels.

Learn more about

Bachelor of Applied Science (BASc): Civil, Electrical, Mechanical

3-D tissue models enable safer drug screening and more effective regenerative therapies. The advantages of bio-printing advantages include accurate control of cell distribution, scalability and cost-effectiveness.

“We hope this new bio-ink will help researchers create improved artificial organs and lead to the development of better drugs, tissue engineering and regenerative therapies,” Kim says.

Using a patient’s own genetic material to produce a body tissue, he adds, can minimize or eliminate the rejection risks faced by tissue or organ transplant patients.

Weaving Body Tissue

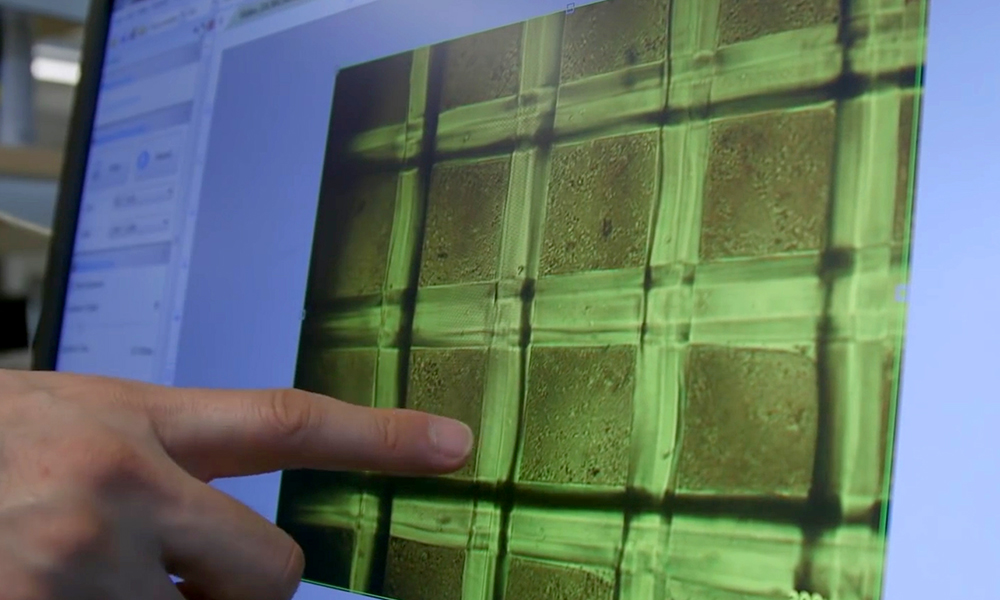

Tissue is created much like tapestry on a loom with individual micrometre-sized strands woven together to collectively strengthen the structure.

Kim isn’t just satisfied with creating the bio-printing output, he and his team are also designing tools to more effectively conduct their research. They have developed high-speed, cheap and efficient video equipment and micro/nano grippers for sensors to assist in handling the engineered materials.

A microscopic view of engineered tissue

In many cases, the human body will adapt and reinforce engineered tissue materials that it deems suitable. Though in many cases, it won’t and the recipient’s immune system will reject and destroy the transplant.

Creating a consistently suitable material with a combination of organic and synthetic components will lead to the next great breakthrough in this area of research. Combining that material with the appropriate bio-printing technique is the researchers’ current challenge.

“We have many new tools at our disposal,” says Kim. “And we are confident that one day, in the not too distant future, we will eliminate the rejection risks facing tissue transplant patients.”