GROWING UP IN IRAN, DR. MOHAMMAD ZARIFI WAS A STARGAZER. But he wasn’t fixated on movie stars or singers like so many kids in the West — the celebrities Dr. Zarifi looked up to were astronomical; brilliant stars like Betelgeuse, Rigel and nebulas in the universe. On many cloudless nights in the northwestern city of Tabriz, Dr. Zarifi pointed a telescope towards the dark sky above the nearby Eynali mountain range, marvelling at the celestial wonders before him.

“I was thrilled with astronomy,” says Dr. Zarifi, an assistant professor in UBC Okanagan’s (UBCO) School of Engineering. “I read most of the books in local bookstores about astronomy and how to find new stars.”

Assistant Professor Mohammad Zarifi.

As a teenager, he eyed a future in pure astronomy, though his father nudged him towards his own field of physics. “But then,” Dr. Zarifi recounts, “I noticed another way to follow my passion in astronomy. For all those astronomical discoveries, most of the time you need specialized instruments, and electrical engineering and electronics gives you the skills to make those instruments.”

Dr. Zarifi’s practical nature ultimately won out over his theoretical side. He pursued studies in engineering with the intention of inventing and making amazing devices that would have practical applications on Earth and in outer worlds.

He eventually earned a PhD in electrical and computer engineering from the University of Tabriz, although he didn’t end up making new tools for astronomy. Instead, he researched high-speed/low-power analog circuit design and analog-to-digital converters (ADCs) — devices that, for instance, help capture and convert sound waves into bits and bytes that can then stream music on a computer or smart phone. Some of Dr. Zarifi’s other work focused on designing tiny electronic devices for use in biomedical applications. “I was looking at implantable devices that could go inside the brain to record neural signals.”

Hoping to expand his education and continue his research abroad, Dr. Zarifi knew of a highly-accomplished Iranian electronics engineer teaching at the University of Alberta (U of A) by the name of Dr. Mojgan Daneshmand. Dr. Zarifi contacted her, and, in 2013, he secured a postdoctoral fellowship with Dr. Daneshmand.

At U of A, Dr. Zarifi conducted research on nano-thin “planar” (flat) structures and how they could be used as part of ultra-sensitive microwave sensing devices for the oil and gas industry. His mentor soon became a friend, and Dr. Zarifi continued working with Dr. Daneshmand even after finishing his postdoctoral research and moving to Kelowna to join UBCO in September 2017.

“Mojgan,” Dr. Zarifi says in a softening voice, “was brilliant. She won lots of awards.”

Tragically, Dr. Daneshmand, her husband Dr. Pedram Mousavi (also a U of A engineering professor), and their two young daughters were among 176 people killed on Ukraine International Airlines Flight 752 as it departed Iran on January 8, 2020.

Dr. Zarifi particularly remembers Dr. Daneshmand’s exuberant teaching style. “When she came to the lab, she would jump on the tables. She was so enthusiastic and fun.”

From a bookshelf in his UBCO office where he keeps mementos — a puck from the U of A hockey team (“I never played but I was a big fan,” he says) and a “moon ball” souvenir from Florida’s Kennedy Space Center — Dr. Zarifi pulls down something else. It’s a photo of him and Dr. Daneshmand smiling together at a recent engineering conference.

It’s hard to look at now.

Mojgan Daneshmand (centre) and Mohammad Zarifi (right) at an engineering conference in 2018.

Resourceful Researcher

Since arriving at UBCO, Dr. Zarifi has shown his entrepreneurial chops, building a new microelectronics teaching and research program from the ground up.

He needed a number of things: a lab, research students, and industrial partnerships and other grants to support the market-driven research and development of his group. Dr. Zarifi wanted to compete in the race to miniaturize microelectronics used in industry, and he wanted to advance the use of more portable, faster microwave sensors that are impervious to hazardous environments. It was tough going at first.

Every proposal to government and institutional funders, such as the Canadian Foundation for Innovation (CFI), required a convincing argument, explains Dr. Zarifi. The research had to be both innovative and bring potential benefit to Canadian society. “The proposal had to capture the next five years of my research. That takes a lot of effort,” says Dr. Zarifi, who ultimately succeeded in securing a number of important grants.

He also shopped and he bargained. “I put all my efforts into buying and purchasing whatever state-of-the-art instruments I could. I wanted my students to be exposed to those kinds of instruments.”

As his OMEGA (Okanagan Microelectronics & Gigahertz Applications) Lab took shape, Dr. Zarifi sought students to fill it. Almost daily, he received more than 50 emails from prospective students across Canada and abroad. He put their CVs through his mental grinder, granting interviews to the best prospects. He now has five post-doctoral researchers, eight master’s students and three senior undergraduates — all working with him in the OMEGA lab on various projects.

Partnering Up

As the lab progressed and students came, Dr. Zarifi began searching for another important component of his plan; companies with potential applications for his microelectronics and microwave research. He searched websites and LinkedIn to identify industries where advanced microwave sensors, ADCs and other Micro Electro-Mechanical Systems (MEMs) could enhance their products. Then Dr. Zarifi rang them up.

“The first calls to those companies can be a bit weird,” he admits. “Companies are usually waiting for someone to call them and ask them about buying their products. But I’m calling them because I want to have collaborations. At the same time, you also want some support from them.”

Since coming to UBCO, Dr. Zarifi, as a principal and co-investigator, has managed to wrangle $4 million in grants for research projects at UBCO. And he’s so good at forming collaborations from cold-calls that he won first place in the 2015 industrial collaboration competition from the National Research Council of Canada.

“In a highly competitive environment for hiring engineers, we’ve found that when we need to cue up additional staff for various and highly-specialized projects, UBCO graduate students can ramp up just as quickly as some engineers and researchers with several years of experience.”

One industry prospect Dr. Zarifi partnered with is ESS Technology (ESS), a California-based manufacturer with a Kelowna branch that specializes in high-performance mobile, automotive and audiophile sound systems. The company makes microchips and audio-to-digital converters used in smartphones, high-end headphones, gaming sets and hearing aids for companies such as Samsung, Sony, Yamaha and Kenwood.

When Dustin Forman, Senior Vice-President of Engineering at ESS, looks around his Kelowna office, he estimates that more than 30 per cent of the employees there are former UBCO students.

“In a highly competitive environment for hiring engineers, we’ve found that when we need to cue up additional staff for various and highly-specialized projects, UBCO graduate students can ramp up just as quickly as some engineers and researchers with several years of experience.”

Forman adds, “In partnership with ESS, the OMEGA lab team is working on innovating and shrinking integrated circuits that could be used to improve devices like hearing aids and smart phones.”

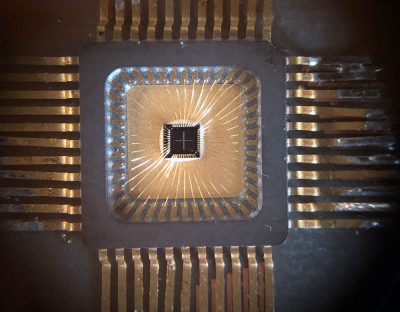

This integrated circuit sensor is used to detect hazardous liquid materials, up to the nanolitre.

Dr. Zarifi proudly shows off one of these tiny audio processing chips — about the size of a baby’s pinkie nail — that was the first-ever chip fabricated based on a UBCO design.

In addition to making these chips smaller, Dr. Zarifi’s team is also examining ways to lower their power consumption. That’s a critical objective for ESS’ future competitiveness, since audio technology evolves rapidly. “By the time you send a chip out into production, you’re already one cycle behind,” says Forman.

He adds that since many devices ESS chips are installed in run off battery power, “The real push right now for us is to lower the chips’ power consumption. Power consumption is a dominant factor in a lot of these products.”

Big Thinking by Shrinking

At the OMEGA lab, a quiet hive of activity is taking place. Dr. Zarifi and his students may be shrinking the size of chips but they’re stretching the possibilities of MEMS, microwave sensors and other chip-based technologies. The devices they’re working on could provide new kinds of sensors to sniff out just a few molecules of errant gasses, or help aircraft navigate poor weather conditions.

Each student working in the lab on ESS chips is working on a subsection of the components needed for the project.

In one corner, Katherine Luckasavitch, a second-year electrical engineering master’s student, sits at her desk next to a tilting stack of papers on a windowsill. She pulls up a program called Cadence on her computer. She’s using it to help design and conduct simulation tests of complex, integrated circuitry for a chip that would shrink and improve the function of the audio-to-digital converters intended for a new generation of smaller hearing aids.

“It’s been tricky at times,” admits Luckasavitch. “We actually just came across a problem.” A transistor behaved weirdly during a test simulation when she pushed input voltage above 600 millivolts.

Although she spends hours at the lab, sometimes weekends— especially when such technical problems come up — Luckasavitch loves the challenges of her work.

Electrical engineering master’s student Katherine Luckasavitch.

“Everyone gets their hands dipped in everything in this lab,” she says. “One second you’ll be working on an audio-to-digital converter, and the next, it’s on a microwave sensor. There’s a lot of opportunity to learn.”

Luckasavitch is supported by a Mitacs research grant, which funds her part-time work at ESS Technology. She spends the rest of her time at the OMEGA lab, working on those micro-electronic components that could go into future ESS products.

Without the funding, Luckasavitch says she would need to work at an unrelated part-time job, thereby undermining her lab time and studies. “Through the Mitacs program I’ve been able to get awesome hands-on experience I probably wouldn’t have had otherwise.”

An Icy Situation

Ryan Kozak, a first-year master’s student in engineering, has been working in the OMEGA lab since his undergraduate days. He’s helping develop an ice-sensing device with aviation applications. Icing — a build-up of a thin layer of ice on wing surfaces — is one of the most common causes of aircraft crashes.

Currently, the primary way for pilots to detect icing with any confidence is to look out the window at their wings. “They haven’t really figured out a better, permanent solution for that,” explains Kozak.

In a separate project, the OMEGA lab developed a prototype sensor that could detect a narrow band of microwave frequencies when reflected off ice. Kozak used his skills to construct an apparatus called a Peltier cooler. The lab used it to chill and build up ice on a metal surface, similar to a wing surface, for conducting the prototype tests with microwaves.

Engineering master’s student Ryan Kozak.

In his last year of undergraduate studies Kozak wrote a paper on the research, which was submitted in December 2019 to the IEEE Transactions on Industrial Electronics journal for peer review. It’s a rare and exciting opportunity for an undergrad student at a Canadian university, says Kozak. He credits UBCO’s tight-knit learning environment for making the accomplishment possible.

“This wouldn’t have happened if I attended any other school. The reason that I was able to do this is because the program is so small and I actually got to know Dr. Zarifi quite well while taking his courses.”

Kozak says friends in undergraduate programs at other universities can’t even get near a lab, never mind take an active role in a research project that could one day make air travel safer. “That’s pretty sweet,” he says.

It’s clear from Kozak’s testament that the OMEGA lab is a space where student researchers can challenge, engineer and discover.

And it’s all thanks to Dr. Zarifi, a big thinker whose curiosity hasn’t faded one bit since those celestial wonders above Iran captured his boyhood imagination so many years ago.