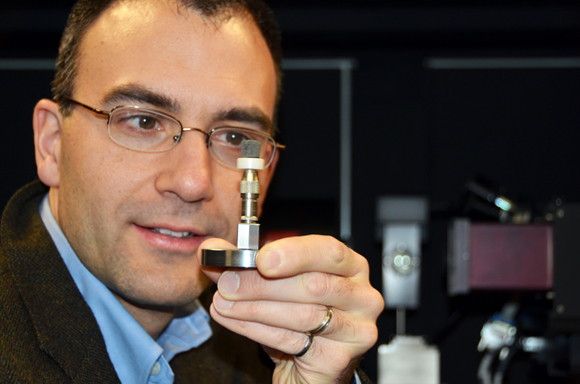

André Phillion demonstrates how small the samples are that will be imaged by the 3-D X-ray CT microscope. He can later view a picture magnified 1,000 times and in 3-D imagery on his computer monitor.

Health and manufacturing sectors to benefit from X-ray CT microscope

3-D X-ray technology could pave way for new generation of defect-free, lightweight cars and planes. Instead of reinventing the wheel, the goal of one UBC researcher is to make wheels, and other manufactured materials, lighter, stronger, and safer.

UBC Assist. Prof. André Phillion peers inside the 3-D X-ray computed tomography microscope while he gets ready to take an image of a small sample in 3-D.

Once the domain of science fiction, the recently installed 3-D X-ray computed tomography (CT) microscope at UBC’s Okanagan campus is allowing experts to peer inside the internal structure of materials and explore a 3-D image, magnified 1,000 times. It’s the first step towards lighter and stronger resources that can be used in most industries including aerospace, energy, and manufacturing, says UBC School of Engineering Assist. Prof. André Phillion.

The leading-edge technology—this is B.C.’s first high-resolution CT scanner, and one of only five in Canada—provides highly-magnified, internal pictures that can be examined in great detail. For those in the manufacturing industry, this opens the window to determine how defects can form and how they can lead to failure. Phillion uses the basic aluminum alloy automobile wheel as an example.

“We know that stress causes fatigue and we know how metals respond to stress,” Phillion says. “What we’re asking is, ‘Can we predict a potential flaw in the wheel and then eliminate potential danger?’ ”

Phillion says UBC’s machine is different from the CT scanners found in most hospitals, since the magnification is much greater. He is not aware of anyone in Canada using this technique to study manufacturing. In UBC’s lab, investigators can take a sample about the size of a pinkie finger and magnify it more than 1,000 times its original size to reveal the internal structure of the material. Defects then become visible.

The research not only improves manufacturing processes, like the casting of aluminum alloys for wheels, but also enhances performance and, ultimately, the lifetime of the component.

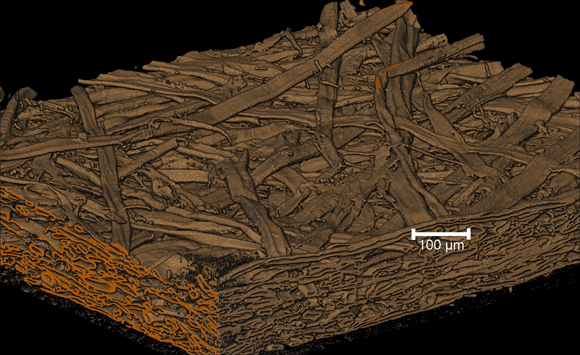

“We are currently looking at a wide range of materials—metals, composites, paper-based products—and trying to decipher images that are enormously complex,” Phillion says. “The end goal is to make products that are lighter and have fewer defects, and to also find new uses for traditional materials.”

In the future, one could imagine a world where metal castings are designed so that areas prone to deficiencies are thicker, while areas that are defect-free are thinner, to reduce weight, says Phillion.

“We may be able to use recycled aluminum alloys in aerospace applications to reduce costs, or maybe design a hydrogen fuel cell that operates more efficiently,” says Phillion.

Phillion is currently working with CanFor Forest Products to study paper fibres. He foresees that one day paper-based products may be made from controlled processes that limit the amount of expensive softwood required.

Phillion is excited about the research underway at UBC’s Okanagan campus with this new equipment. It’s a tool, he says, that will one day change the world.

“High-resolution CT technology is transformational. The ability to see things in 3-D gives us a new understanding of how materials are manufactured and how they can be used,” Phillion says.

How tomorrow’s technology may save lives today

While André Phillion’s 3-D X-ray computed tomography (CT) microscope at UBC’s Okanagan campus is working to improve manufacturing materials of the future, it has caught the attention of health researchers. Phillion is currently working with Vancouver’s Jim Hogg Research Centre to study Chronic Obstructive Pulmonary Disease (COPD). By placing small fragments, perhaps 10 mm in diameter, of a diseased lung into the 3-D X-ray machine, experts can examine highly magnified images of the tissue.

“We are able to look at the structure of lung tissue in 3-D,” says Phillion. “We hope to learn what’s happening to the lung at the very early stages of the disease to suggest treatment before it causes more damage.”

This is exciting news for Assoc. Prof. Neil Eves, co-director at the Centre for Heart, Lung and Vascular Health at UBC’s Okanagan campus. COPD is not just a smoker’s disease, Eves says, as it is caused by exposure to any noxious particles or gases, which can damage airways and lung tissue.

“COPD is a disease that is rapidly growing around the world, and there is considerable need for research to allow us to better understand how the disease first presents and then progresses,” Eves says. “Better understanding of the early processes and early detection are paramount to slowing the progression of this devastating disease and reducing its impact on society.”

This is a 3-D image of a piece of paper magnified in UBC’s newly-installed 3-D X-ray computed tomography microscope.

—30—