A droplet of fuel mixed with nanomaterials is ignited during an experiment in UBCO’s Combustion for Propulsion and Power Lab.

The goal of creating a cleaner fuel for aircraft engines is creating a spark at UBC Okanagan.

A team of researchers studying the burning rate of nanomaterials in liquid fuels believe they have created a recipe for clean-burning, power-boosting aircraft fuel. The project is a collaboration between the School of Engineering’s Combustion for Propulsion and Power Laboratory (CPPL) and its Nanomaterials and Polymer Nanocomposites Laboratory.

Inside the CPPL, researchers watch a bright consistent flame as it dances over wires containing droplets of liquid fuel enriched with nanomaterials. The team is investigating the combustion characteristics of microscopic graphene oxide inside fuel.

Their experiment measures the ignition delay, burn rate and speed by which the graphene particles and fuel separate into smaller particles.

“Working with our industry partner, ZEN Graphene Solutions, we are assessing how the burn rate of this mixture can potentially improve its combustion properties,” explains lead author and doctoral student Sepehr Mosadegh.

Mosadegh and his supervisor, Assistant Professor Dr. Sina Kheirkhah, develop technology, tools and knowledge for next-generation energy and aerospace-related applications. In this case, they hope their results will lead to a future of cleaner and more powerful aircraft.

“When it comes to fuel, we are always searching for a consistent response of the fuel within key parameters as they relate to how it ignites, burns and maintains strength,” says Mosadegh. “Most people have a general understanding of the composition of gasoline and jet fuel, and that it is a mixture of many hydrocarbons. But they may not think about how combining these with nanomaterials and burning them can result in dramatically more powerful and cleaner engines.”

Using ultrafast and intensified cameras and microscopy analysis, the researchers were able to study the combustion rate of the doped fuel. They found that the addition of graphene oxide nanomaterials into ethanol improved the burn rate by about eight per cent. This improvement in combustion, the researchers explain, can help reduce the carbon footprint of aircraft. And at the same time, make aircraft more powerful.

“The recipe for cooking the nanomaterials was developed by the co-author of this study Ahmad Ghaffarkhah, who works in our partner lab,” says Dr. Kheirkhah. “We have published the results for doped ethanol, and we have promising results for other liquid fuels such as jet A and diesel.”

The addition of nanomaterials to liquid fuels alters the heat transfer and the fuel’s evaporation rate, impacting the overall burning rate.

“However, getting just the right mixture of nanomaterials and liquid fuel is key to improving combustion. Particularly in aircraft engines,” Dr. Kheirkhah adds.

The research appears in Combustion and Flame and is funded by the Natural Sciences and Engineering Research Council Canada through a Collaborative Research and Development Grant awarded to Dr. Kheirkhah and Dr. Mohammad Arjmand, Canada Research Chair (Tier 2) in Advanced Materials and Polymer Engineering.

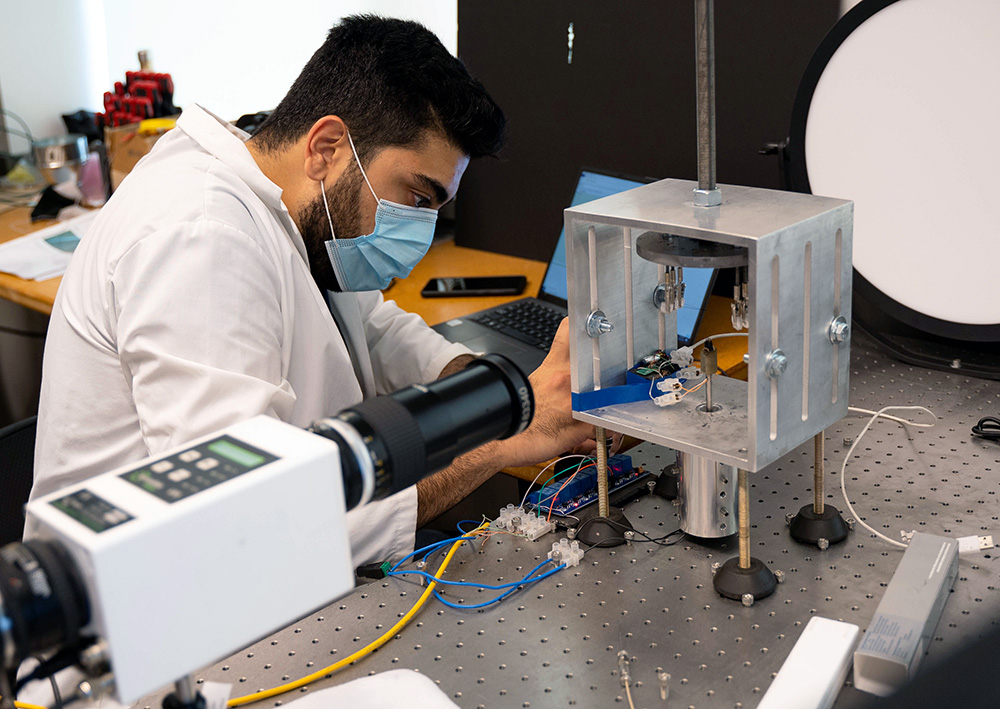

UBCO researcher Sepehr Mosadegh tests the ignition delay and burn rate of fuel mixed with graphene oxide with the hopes of creating a greener, but more powerful, aircraft fuel.